Bringing ideas to like, one layer at a time

About Us

RIFTWAY SOLUTIONS

Experience the Cutting Edge World of Rapid Prototyping

About RiftWay

- Welcome to Riftway Solutions—where innovation meets precision in the world of additive manufacturing. We are committed to transforming your digital blueprints into tangible realities. Our team of dedicated professionals harnesses the latest in additive manufacturing technology to deliver high-quality solutions tailored to meet your unique needs.

- At Riftway Solutions, we believe that the future is molded by the ideas we bring to life today. Our state-of-the-art equipment and skilled specialists are at the forefront of the additive manufacturing revolution, ensuring that every project from prototypes to final products surpasses your expectations.

- Our mission is simple: to provide cutting-edge additive manufacturing services that empower individuals and businesses alike to innovate, design, and create without limits. Whether you’re an engineer, designer, entrepreneur, or hobbyist, Riftway Solutions is here to turn your visions into reality.

- We pride ourselves on our commitment to sustainability and efficiency, continually improving our processes to minimize environmental impact while maximizing quality. Join us at Riftway Solutions, where we’re not just printing objects—we’re building the future.

RIFTWAY SOLUTIONS

Our Specialities?

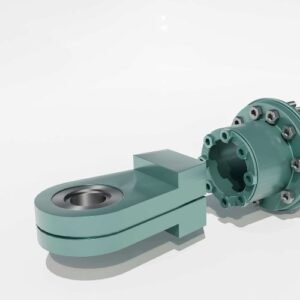

3D Printing

in Metal

Precision, durability, complexity revolutionize industries with innovation.

Functional Prototyping

Iterative creation of working models for testing and validation.

Product

Engineering

The process of designing and developing innovative, functional products.

3D Scanning & Modelling

Capturing real-world objects digitally for replication or modification.

Conceptual Modelling

Creating abstract representations of systems for comprehension.

Reverse

Engineering

Analyzing a product to understand its design, structure, or functionality.

RIFTWAY SOLUTIONS

Why Choose Us?

- Unmatched Expertise: At Riftway Solutions, our team is composed of industry-leading experts with extensive experience in additive manufacturing. We stay ahead of the curve through continuous training and staying updated with the latest advancements in the field.

- Customized Solutions: We understand that every project has unique requirements. That’s why we offer tailored solutions that precisely fit your specifications. From the initial concept to the final product, our focus is on delivering exactly what you need.

- Advanced Technology: Leveraging state-of-the-art technology, we ensure superior quality and precision in every print. Our facilities are equipped with cutting-edge machinery that can handle a wide range of materials and complex designs.

- Speed and Efficiency: Time is of the essence in bringing ideas to life. We are committed to rapid turnaround times without compromising on quality. Our efficient processes and responsive customer service make it possible to meet your tightest deadlines.

- Sustainable Practices: We are dedicated to sustainability. Our additive manufacturing processes reduce waste and energy consumption compared to traditional manufacturing methods. Choosing us means opting for a greener future.

- Competitive Pricing: We provide top-notch additive manufacturing services at competitive prices. Our cost-effective solutions ensure that you get the best value for your investment.

- Customer-Centric Approach: Your satisfaction is our top priority. We work closely with you throughout the entire process to ensure that your expectations are not just met, but exceeded.

- Choose Riftway Solutions to experience the future of manufacturing—where your ideas gain form and function effortlessly and efficiently.

Process Flow :

Digital Design

We initiate our process with a meticulous digital representation of the envisioned object, crafted using advanced computer-aided design (CAD) software. This stage sets the foundation for precision in the final product.

Slicing

The CAD model is segmented into ultra-thin layers. This critical step creates a detailed blueprint that guides the printing process, ensuring accuracy down to the finest details.

Material Preparation

Our metal additive manufacturing utilizes high-grade powdered materials such as stainless steel, titanium, and aluminum. This choice of materials ensures durability and functionality in the final product.

Printing

Equipped with a potent laser or electron beam, our metal 3D printers meticulously melt or fuse the metal powder. The process is executed layer by layer, adhering strictly to the design specifications to build the object with unparalleled precision.

Layering

The object is constructed through a continuous layering process. Each layer is fused perfectly before the next is added, gradually forming the complex geometries and intricate details of the final object.

Post-Processing

Following the completion of the print, the object undergoes several post-processing steps. These may include the removal of any support structures, heat treatment to enhance mechanical properties, surface finishing for aesthetic and functional quality, and rigorous inspection to ensure that every aspect of the object meets our high standards.

Advantages :

Precision Engineering

Our metal additive manufacturing technology facilitates the creation of exceptionally precise and intricate designs. This ensures that every component meets the highest standards of quality and accuracy, crucial for demanding applications.

Customization

With the ability to tailor metal parts to specific requirements, we provide unparalleled customization options. This adaptability is essential for serving a broad spectrum of industries with unique needs.

Rapid Prototyping

Accelerate your product development cycle with our rapid prototyping services. This capability allows for swift iterations and timely adjustments, significantly reducing time-to-market for new ideas.

Complex Geometries

Our advanced technology enables the production of components with complex geometries that are impossible to achieve through traditional manufacturing methods. This opens up new avenues for innovation and distinctive product designs.

Lightweight and Durable

We produce components that are not only lightweight but also exceptionally durable, ideal for critical applications in aerospace, automotive, and other sectors where performance is paramount.

On-Demand Production

Our on-demand production model minimizes the necessity for extensive inventories and enhances manufacturing flexibility, adapting quickly to market demands and production schedules.

Sustainability

We are committed to sustainable manufacturing practices that reduce material waste and utilize energy-efficient production methods, contributing to a greener manufacturing sector.

Versatile Materials

Our facilities are equipped to handle a diverse array of metals, including maraging steel, titanium, and aluminum, catering to varied applications across multiple industries.

Personalization

We specialize in delivering highly personalized products designed to meet individual customer specifications, fulfilling the growing demand for customized market solutions.

Innovative Additive Manufacturing Solutions by RIFTWAY SOLUTIONS

On-Demand manufacturing offers industries flexibility, cost reduction, customization, sustainability and simplifying the supply chain