Bringing ideas to like, one layer at a time

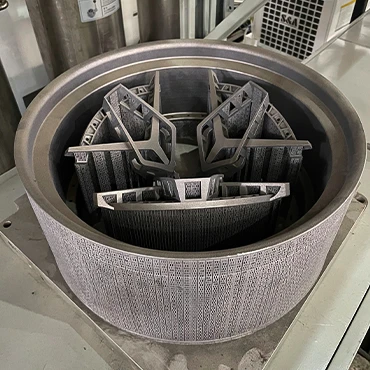

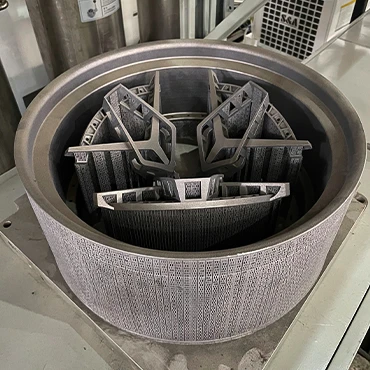

Metal 3D Printing

Direct Metal Laser Sintering (DMLS)

Materials

Aluminium-Silicon

Stainless Steel

Maragin Steel

Titanium

In718

Process Flow :

Digital Design

A digital representation of the object is created using computer-aided design (CAD) software.

Slicing

Material Preparation

Printing

Layering

Post-Processing

Advantages :

Precision Engineering

Achieve precise and intricate designs with metal 3D printing technology, ensuring your components meet the highest standards of quality and accuracy.

Customization

Benefit from the freedom of customization, tailoring metal parts to your specific needs and designs for a wide range of industries.

Rapid Prototyping

Speed up your product development cycle with rapid prototyping, enabling quick iterations and design adjustments to bring your ideas to market faster.

Complex Geometries

Create components with complex geometries that are unattainable through traditional manufacturing processes, ensuring innovation and unique product designs.

Lightweight and Durable

Benefit from lightweight yet durable components, perfect for applications in aerospace, automotive, and other industries where performance matters.

On-Demand Production

Embrace on-demand production, reducing the need for large inventories and offering flexibility in manufacturing.

Sustainability

Embrace environmentally friendly manufacturing practices with reduced material waste and energy-efficient production methods.

Versatile Materials

Utilize a variety of metals such as maraging steel, titanium, and aluminum for a wide range of applications in multiple industries.

Personalization

Offer highly customized products tailored to individual customer needs, catering to the demands of a personalized market.

Innovative Additive Manufacturing Solutions by RIFTWAY SOLUTIONS

On-Demand manufacturing offers industries flexibility, cost reduction, customization, sustainability and simplifying the supply chain